Main | Winding

the Coils | Cutting the Rings | Knitting

the Maille| List of Weaves

My Armour

Project | My Other Projects | Accessories

| List of Armour Terms

This page is currently

under construction.

Please be patient

while I get it working.

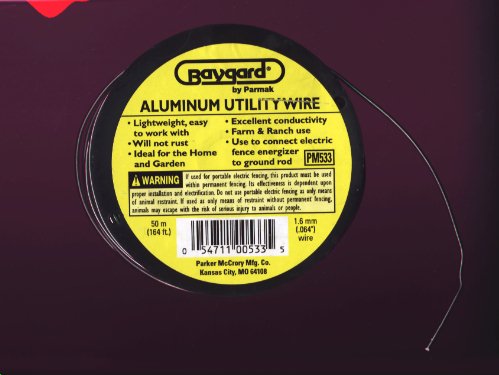

Wire:

This is what you will be making you

maille out of. Wire is easily obtainable from just about any hardware

store or building centre. If you are planning on a large project

however, I recommend getting your wire from a local farm supply store,

where large rolls of wire are sold for fencing. I recently purchased

a quarter mile spool of 16 gauge wire from a farm supply store for $26.00

CDN, for example, which works out to about 6 1/2¢

CDN per metre, or roughly a third of the cost of the smaller 15 metre rolls

sold at the hardware store. Thatís a good thing, because you are going

to need a lot of wire.

Wire is sold in a range of different

gauges, which determine the thickness of the wire. The higher the

gauge number of the wire, the thinner the wire is.

Unfortunately, there are two different

standards for wire gauges; American Wire Gauge (AWG), which is used in

the United States, and Standard Wire Gauge (SWG), which is used everywhere

else in the world. Just as the American gallon is smaller than the

Imperial gallon, wire conforming to the American Wire Gauge is noticeably

thinner than wire made using the Standard Wire Gauge. This can be

a real problem when you are trying to keep the look of your rings consistent,

and mix the two gauge types by accident. Try to avoid mixing the

two gauge types.

A Mandrel:

|

A mandrel is possibly the most important

single tool for making maille, since it is required for turning your wire

into coils.

... er ...

... Wait a minute ...

Wrong picture.

Iím talking about a mandrel, not

a mandrill. |

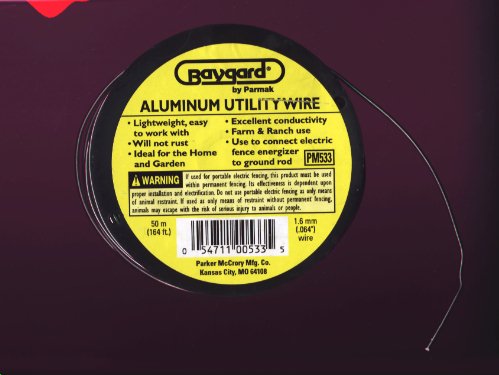

Ah. Thatís more like it.

The mandrel itself is a steel rod

(It can also be a wooden dowel) with a diameter equal to what you want

the inner diameter of your rings to be. In order to allow you to

turn it, one end of the mandrel is bent into a crank arm.

The mandrel fits into a stand, which

consists of a base with two uprights. The uprights on the stand in

the photo above are made of metal, but this is not necessary. In

most cases, the uprights are made of wood.

Please see the Winding

the Coils for more information on making your mandrel.

Power Drill (Optional):

This is optional for people who are

too lazy to to turn the mandrel by hand. Personally, I think this

is rather hazardous, and I donít really recommend it.

Winding Jig (Optional):

A winding jig is a special kind of dance you do while you are winding

your coils.

What?

You want the real definition?

Groan...Okay.

A winding jig is a special tool you can construct for winding coils

with a power drill. It serves as both a convenience and a piece of

safety equipment. (More detailed information coming soon.)

Wire Cutters or Aviation Snips:

For cutting coils into rings.

Of the two, aviation snips are better, as they produce a better quality

cut, and are much faster.

Rotary Tool with Cut Off Wheels

(Optional):

Also used for cutting rings.

Though relatively slow on steel, a rotary tool produces excellent quality

cutting if you like clean ends for your rings.

Two Pairs of Pliers:

Pliers are to maille what knitting

needles are to wool. They are what you need to use for opening and

closing your rings as you knit. Smaller pairs of pliers are easier

to use than large ones, and make sure the pliers you get have no gripping

teeth, since the teeth can mark up your rings. I use flat nose pliers

to hold the rings, and a pair of bent nose pliers to open and close the

rings. When using the bent nose pliers, I hold them such that the

end curves outward away from my body. I find this orientation very

convenient for manipulating the rings.

Safety Equipment:

If you are cutting rings using a

rotary tool, then safety goggles and a dust mask or respirator are essential,

even if you are cutting the rings outdoors or in a well ventilated area.

Rotary tools have a tendancy to throw

rings as projectiles during the cutting process. Using a wire inserted

down the centre of your coils, or a pair of brackets encasing the coils

can greatly reduce or eliminate this problem. See Cutting

the Rings for details.

If you are winding your coils using

a power drill, you will need to wear a pair of heavy work gloves as you

feed the wire on to your mandrel.

A winding jig (metioned above) can

also be considered a safety device when winding coils with a power drill,

since it keeps your hands away from the rapidly moving wire. See Winding

the Coils for information on how to make one.

ďDis page isnít ready yet.

Now go away, and come back later when it eez feeneeshed, or I shall taunt

you a second time.Ē

Tools and Materials.

Main

| Winding the Coils | Cutting

the Rings | Knitting

the Maille | List of Weaves

My Armour

Project | My Other Projects | Accessories

| List of Armour Terms

![]()